In traditional food and beverage manufacturing supply chains of the past, companies focused attention on areas like supplier performance, deliverability and inventory management with the customer the beneficiary of sound business practices. While this served the needs of the marketplace at the time, priorities have shifted.

From a macro level traditional supply chains operated in a linear fashion. Companies ordered raw ingredients, manufactured them to meet demand and then sold and shipped them to customers.

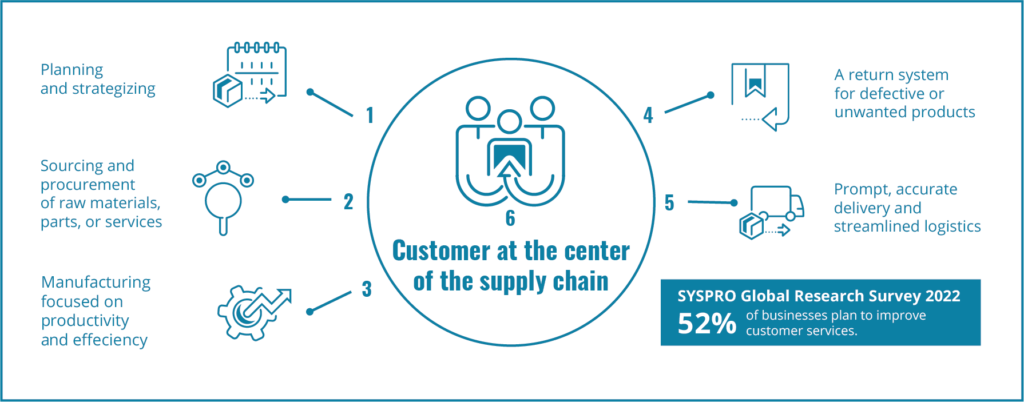

In today’s food and beverage manufacturing environment, successful organizations have taken the supply chain concept further, creating a holistic view of the entire business and making supply chain decisions based upon the needs and demands of customers that sit in the center of the decision-making process, creating a customer-centric supply chain model.

What A Customer-Centric Supply Chain Looks Like

✅ Prioritizing the needs of the most important customers. This doesn’t mean the biggest clients, it means the ones who bring the most value to the enterprise. A smaller customer who brings greater brand recognition could be just as important as the highest volume buyer.

✅ Increasing safety stock for the biggest customers to minimize delivery and production delays and improving on-time deliveries. In today’s business environment ongoing supply chain problems continue to be an issue. 77% of food and beverage companies report ongoing issues with deliveries and supplier order fulfillment. Successful organizations that have traditionally relied on lean manufacturing concepts are now strategically boosting safety stock for their most important partners.

✅ Improved customer communications for better forecasting and demand planning. Gone are the days when customer communications consisted of purchase orders and invoices. Thriving food and beverage manufacturing companies are forging partnerships with customers, collaborating on forecasts, pricing issues and potential new product lines, giving manufacturers better insights for planning purposes.

𝐈𝐭’𝐬 𝐀𝐥𝐥 𝐀𝐛𝐨𝐮𝐭 𝐁𝐚𝐥𝐚𝐧𝐜𝐞

Successful food and beverage company of the future will need to strike a delicate balance, building a resilient supply chain while balancing risk against demand. The best way to accomplish that is through building a supply chain where the customer sits at the center instead of at the end.

The pandemic changed the business landscape for food and beverage manufacturers and distributors. If your business hasn’t adapted to change you’re being left behind by your competitors. What are you doing to adapt?

𝐒𝐡𝐚𝐦𝐞𝐥𝐞𝐬𝐬 𝐏𝐥𝐮𝐠: Need help optimizing your supply chain? We’ve been helping food and beverage manufacturers and distributors for 25-years do just that. Let’s talk about your biggest challenges and how you can address them.

Our Website: https://tech-intl.com or by phone at (909)-614-1416 ext. 120