Imagine this scenario. It’s Monday morning and your purchasing team opens the planning schedule for the week and sees a demand for 3000 pounds of potatoes to meet a sales order for your newest flavored chips.

The team goes into the purchase order module in your system to place an order with your preferred vendor and as they move to complete the request, the system warns them there’s a 37% chance the order will arrive late.

What you are seeing is artificial intelligence (AI) in action. Behind the scenes, AI has analyzed past orders from the vendor, calculated previous on-time deliveries and factored in market factors like shipping issues, routings and past demands and made a prediction based on all those calculations.

Luckily for you, the system gave your purchasing department a heads-up and the team found an alternate supplier to help ensure an on-time delivery to your customer.

It was not that long ago that artificial intelligence existed solely in the realm of science fiction. When people think of AI a lot of them think of HAL 9000, the artificial intelligence being in the movie 2001: A Space Odyssey.

But we have come along ways since the 1968 movie and today AI is commonly used in businesses and embedded in systems around the globe to drive profits, growth and future planning.

Here are three ways it’s being used in food and beverage manufacturing daily.

Quality Measurement and Prediction:

AI can effectively monitor your quality metrics in real time, do a trend analysis and alert you to problems before they happen. Machine learning also allows the identifications of factors that affect the quality of the manufacturing process with Root Cause Analysis so you can eliminate the problem at the source.

On the machine side AI is used to monitor equipment performance. Predictive maintenance analysis-figuring out the time-to-repair and cost-to-repair indicators and categorizing issues and making predictive alerts will provide significant savings to food and beverage manufacturers.

Timely repairs can save up to 50% maintenance time and reduce the costs needed for it by almost 10%.

Predicting Customer Behaviors and Trends

Today’s modern food and beverage company is not just a manufacturer, it’s a technology company. To gain competitive advantage enterprises are relying on AI and predictive analytics to dive deep into the behaviors and buying patterns of its customers.

Businesses have started relying on data points such as demographic information, food preferences, buying behaviors and purchasing history to gain a deeper understanding of the marketplace.

Imagine for a second that a company provides salad kits to large retailers. How valuable would it be to know that a combination of kale, spinach and tomatoes are becoming more desirable to buyers or that they prefer cellophane bags instead of hard-shell plastic containers?

Companies are using AI to track these trends and using the data to help right-size and adjust supply chains and raw ingredient purchasing.

Recipes and Substitutions

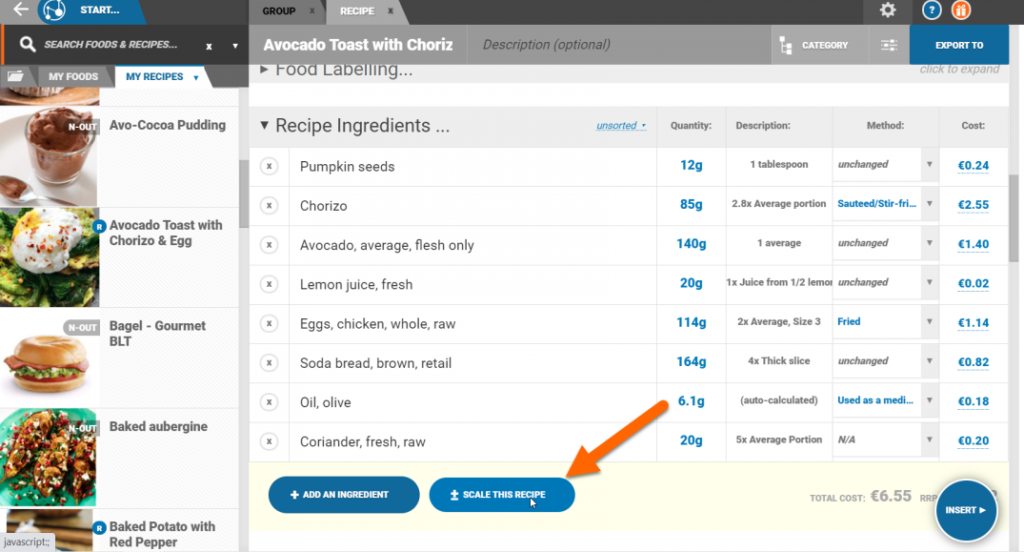

The number of ways we can combine ingredients in recipes is limitless and every food and beverage company has its own closely guarded formulas.

But what happens when businesses want to make a change because of changing consumer tastes or supply chain issues that make substitutions necessary?

It is not just a simple matter of making a simple change like we do in our home cooking; it can take hundreds of hours and dedicated employee teams at a food and beverage company to make one simple swap.

That’s where AI comes in. It can quickly analyze recipes, flavor profiles, colors and textures and then compare it to the original to help businesses determine if it’s worth the effort to make the change, offering significant savings on expenses and time investments. It can also offer alternatives that might be more suitable.

AI is Here to Stay

It is safe to say that Artificial Intelligence and machine learning are not just a passing fad within the food and beverage manufacturing industry. As each day passes more companies discover how it can help boost performance, cut costs and help protect margins. In today’s environment that is imperative if you want to stay competitive and grow.

If AI and machine learning capabilities are not native to your business and ERP systems, it may be time to start thinking about alternatives. It won’t be long until companies without these capabilities will be at a severe disadvantage in the marketplace.

It’s time to embrace AI-just don’t name the system HAL 9000.

Does your ERP system up to the task of offering the most advanced AI and machine learning capabilities? Technologies International, Inc. can help.

Call us today at (909)-614-1416 ext. 120 and let’s talk about putting AI to work for you to help you achieve your goal.

ERP Systems consultants